Tackling Costly Sewage Blockages

In collaboration with Dura Pump

CHALLENGE

A Category B men’s prison in Kent faced continuous issues with its sewage system, leading to frequent blockages that required expensive tankers to remove the waste. Inmates disposing of inappropriate items down the sewage system caused persistent blockages, costing the prison over £50,000 annually.

Despite the inevitability of blockages in the sewage system, stronger pumps designed to manage non-flushable materials could significantly reduce the issue.

The existing system could not manage fibrous materials, plastic, and other non-sewage items, leading to frequent maintenance interruptions.

SOLUTION

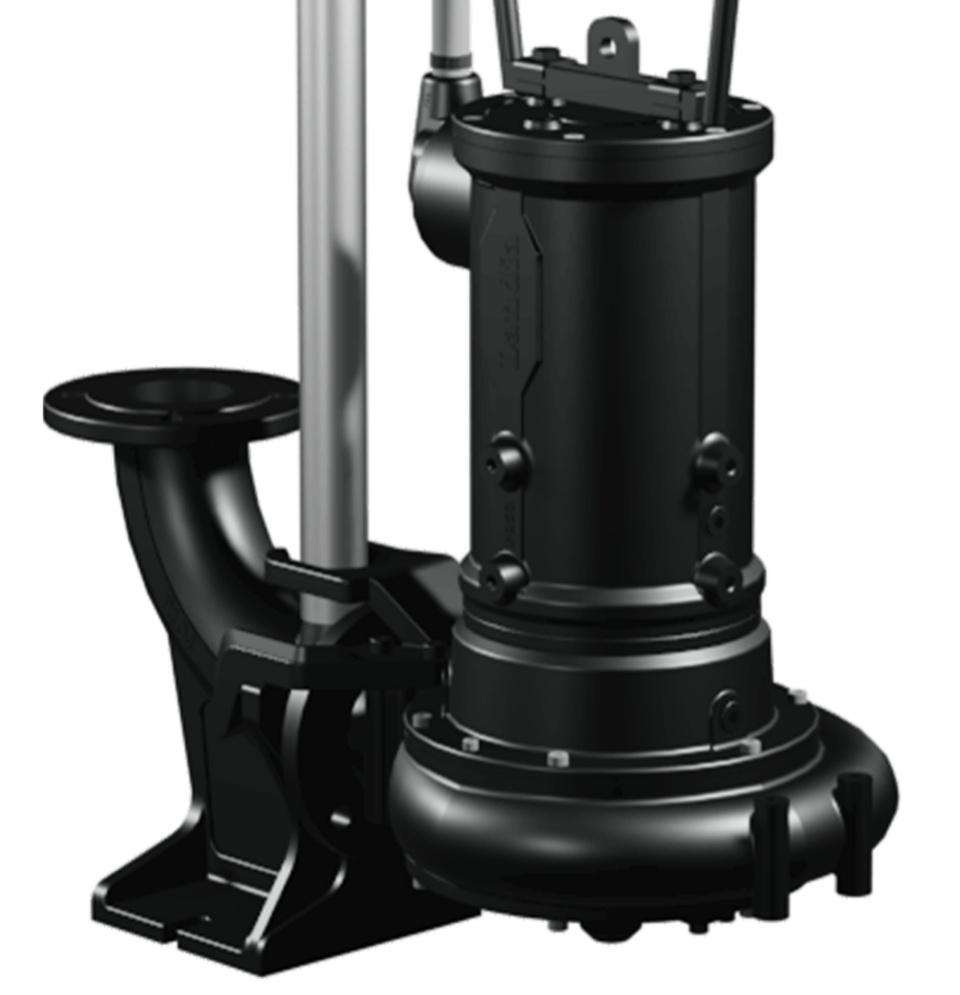

To resolve this costly problem, Dura Pump installed two Landia chopper pumps. These high-efficiency pumps are designed to manage challenging materials by tearing through fibrous substances, cutting plastic into small pieces and crushing brittle items, reducing the need for frequent interventions.

In addition to installing the new pumps, we removed the failed junction box and wired the pumps directly into the control panel.

Technical Specifications:

- Installed 2 x 5.5kW Landia DG-I 80 submersible chopper pumps with extended chopping knife systems.

RESULTS

The installation of the Landia submersible chopper pumps has delivered significant operational and financial benefits:

- Reduced Costs: Twice weekly tankers no longer needed, saving over £50,000 annually

- Minimised Downtime: Fewer blockages and callouts mean less disruption to daily operations

- Improved Monitoring: Upgraded control panel with enhanced alarm visibility, allowing for quicker identification of potential issues

- Faster ROI: The project will pay for itself within four months, thanks to the substantial reduction in maintenance costs.

This efficient solution ensures the prison can operate more smoothly, with fewer interruptions and with better cost management.

Case study originally from www.durapump.co.uk