Chopper pumps for biogas plants

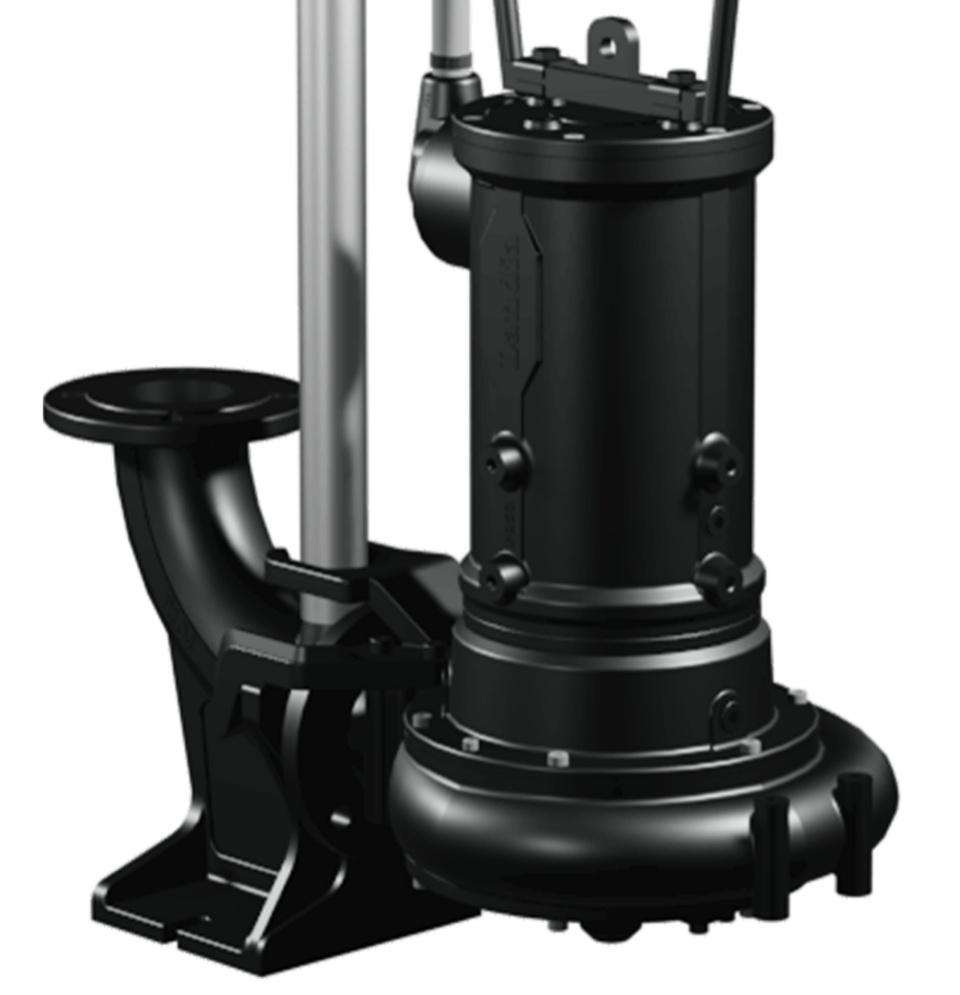

The model DG-I submersible chopper pump is particularly suitable for biogas plants. This heavy-duty chopper pump is designed with an open impeller, which is the ideal design for pumping feedstocks with high dry matter content and high viscosity.

The pump’s unique chopping system, or knife system, proves extremely effective in situations, where large particles and contaminants often create problems for other types of pump.

The benefits of chopper pumps for biogas

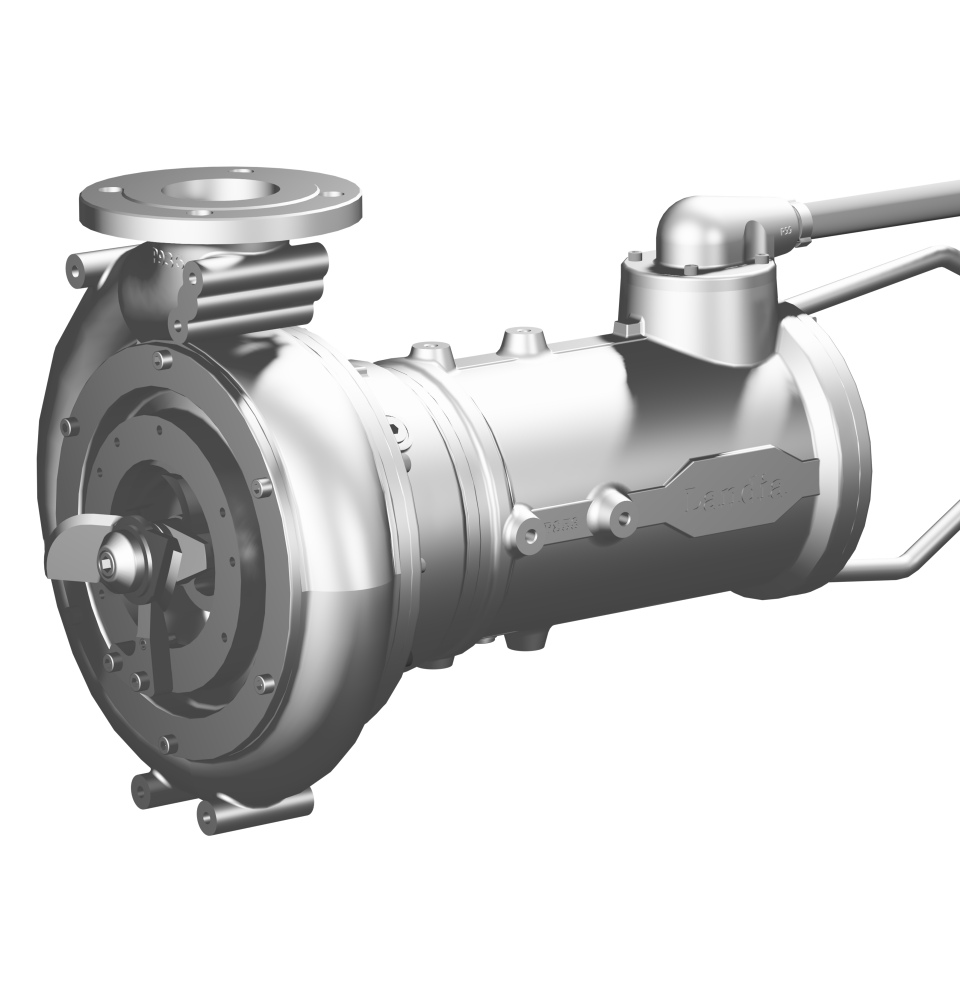

The pump both pumps and chops in one function, which counteracts clogging or blocking. At the same time, it is advantageous for the entire biogas process, which as a result of, reduced particle size gets a biomass that is easier to “eat” for the bacteria in the reactor.

Small foreign objects such as gravel, sand, small shards of glass, bone, etc., can pass through the pump without causing damage and with minimal wear.

The operating range of the pumps is up to 6 bar, which is why they can also replace most types of displacement pumps.

The pump has a simple and robust construction and is easy to service.

For liquids with abrasive particles such as sand, Landia has developed special materials so that the service life of the pump is significantly extended compared to a standard pump.

The pump can be supplied in acidproof steel for operation in aggressive liquids.

Chopper pump DG-I

| Capacities | up to 450m3/h |

| Heads | up to 25m |

| Motor sizes | 0.75 - 37.0kW |

| Available with | Ex motor / IE3 motor |

Our solutions within biogas

Pumps for liquid biomass

Landia’s chopper pumps are flexible and durable pumps that are used to pump different types of biomass between the tanks at the biogas plant.

Hygienisation

Landia’s BioChop hygienisation system is a high-quality solution constructed from simple and reliable components.

From waste to biogas

Many different types of waste products can be extensively recycled in biogas plants. It requires the right pumps and mixers made form the right materials.

A strong partner with extensive experience in biogas

You will not find anyone who has more experience with pumping and mixing solutions for biogas plants than Landia. We have been involved since the biogas industry’s infancy in Denmark, and today you will find Landia products in biogas plants worldwide.

The biogas industry is growing year by year and we are keeping pace.

When you contact Landia, you will speak with employees who know the industry, including some who have worked in biogas plants themselves.